Where quality meets inovation

Transforming companies through thermal efficiency

About

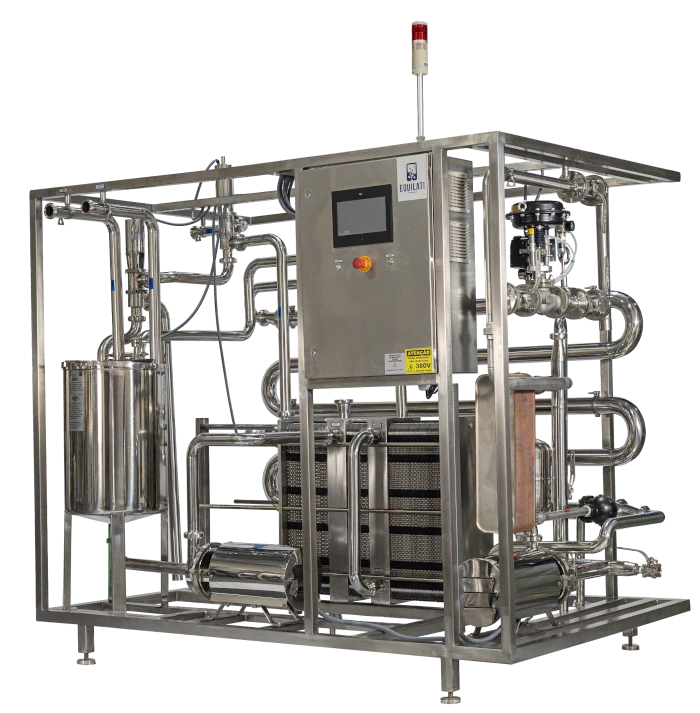

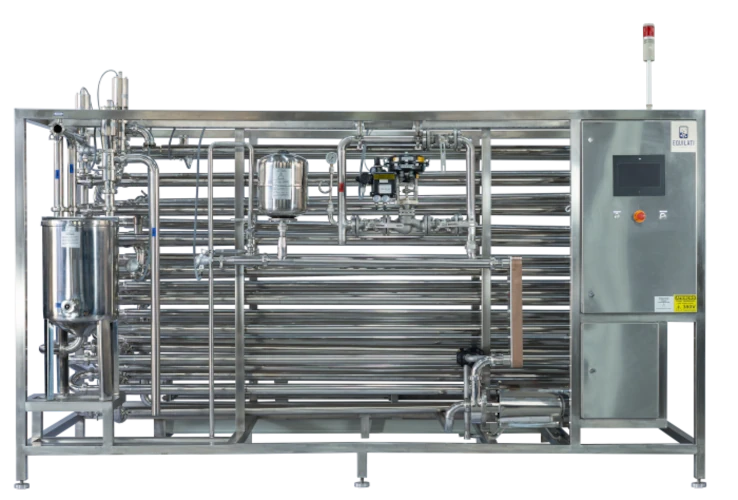

With 32 years in the market, Equilati specializes in the development and manufacturing of pasteurization equipment for various industrial sectors, including food, pharmaceutical, chemical, and petrochemical industries.

- Innovative, affordable, and high-quality products, combining technology with human care.

- To be a national and international reference in pasteurizers and heat exchangers.

- Innovation, Ethics and Transparency, Sustainability, Human Care.

We have a specialized team in each area to better meet our client's needs, from the development of a new project to the complete installation of the equipment.

Learn moreWe integrate advanced technology to deliver modern and efficient equipment.

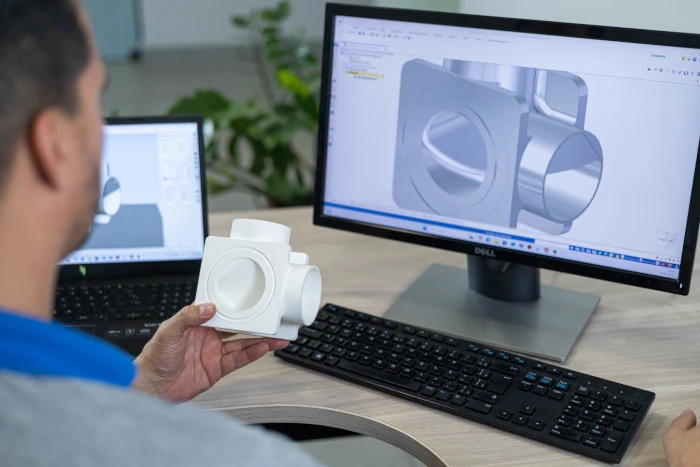

Technology plays a key role in the manufacturing of our equipment, such as pasteurization systems and heat exchangers.

- Automation enables more precise and faster processes, ensuring product quality.

- Meeting the demands of a constantly evolving market.

- Designs that reduce energy consumption and custom projects for each sector.

We seek sustainable, high-performance solutions to meet the demands of each of our clients.

Quality and commitment at every stage of manufacturing.

Our commitment to excellence and innovation begins with the careful selection of raw materials and extends through every step of the production process.

- Processes designed to ensure maximum precision and reliability.

- Rigorous quality tests to guarantee high performance.

- Equipment developed with advanced technology to meet market demands.

Every detail of the manufacturing process is designed to offer durable, efficient solutions aligned with the highest quality standards.

Our team's expertise is essential to quality.

The workforce plays a crucial role in the manufacturing of our equipment, combining technical expertise and dedication at every stage of the production process.

- Highly qualified professionals, committed to precision and excellence.

- Processes carried out with strict standards to meet the highest quality requirements.

- Ongoing investment in team training and development.

The combination of human skill and advanced technologies enables the creation of innovative and reliable equipment, aligned with our clients' needs.

Innovation and technology for a more efficient future.

Innovation is the driving force behind the manufacturing of our equipment, ensuring we are always ahead of market demands.

- Incorporation of new technologies to increase efficiency and precision.

- Integration with IoT systems for greater connectivity and control.

- Commitment to sustainability, reducing waste and environmental impact.

Our commitment to innovation ensures that every piece of equipment is a blend of performance, reliability, and adaptability to new market demands.

Not sure which heat exchanger or pasteurization system is right for you?

Request a quote now and speak directly with one of our specialists!

What we provide

Consulting

With over 32 years of experience, we share our knowledge to help companies optimize their production processes, reduce operational costs, and improve the efficiency of their operations.

Maintenance

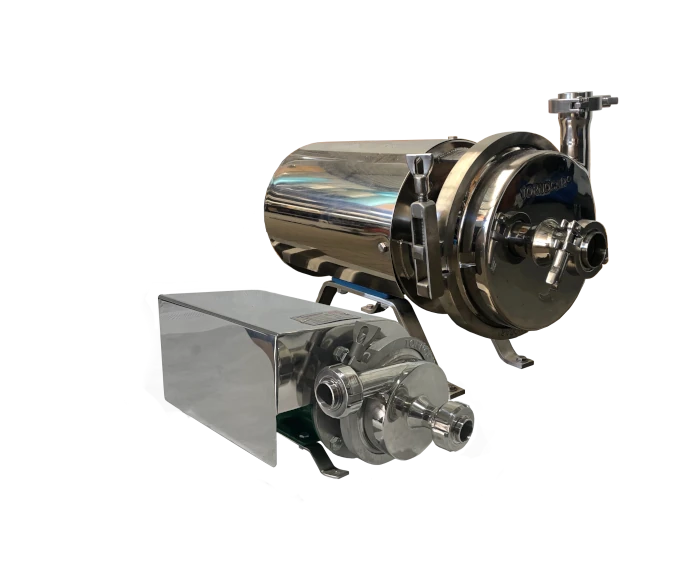

We offer support throughout the entire country, ensuring efficient maintenance of heat exchangers and pasteurization systems.

Assembly

We have extensive experience in the assembly of sanitary lines, using certified food-grade welding to ensure the quality and safety of the processes.

Replacement Parts

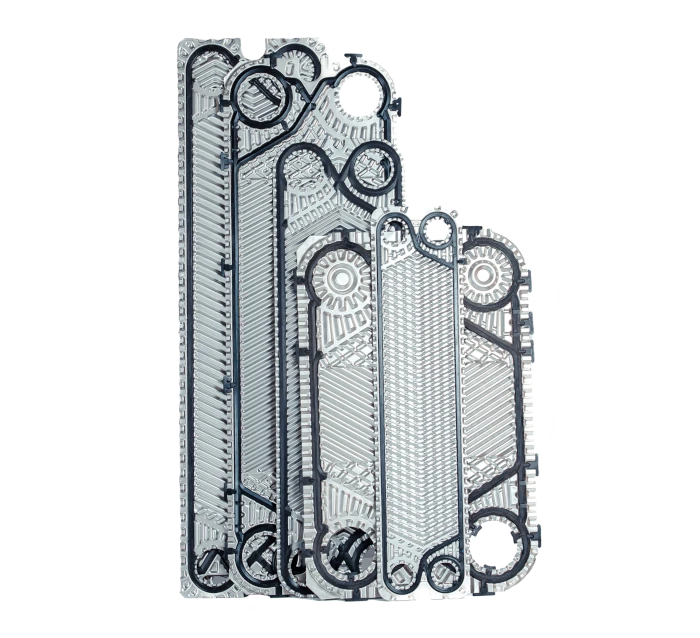

We offer an extensive catalog of spare parts for pasteurization systems and heat exchangers, ensuring equipment efficiency and operational continuity.

Installation

Equilati has a highly specialized team equipped with all the necessary resources to provide installation services for your heat exchangers and pasteurizers.

After-Sales

We offer personalized technical support, remote services, and data-driven information, ensuring efficiency, cost optimization, and maintaining product quality and safety throughout the entire production process.

Equipment

Frequently Asked Questions

I - 3% (caustic soda NaOH). Example: 1.5 kg of NaOH in 50 liters of water. Caustic soda in flakes or liquid form. Temperature: 80ºC.

II – 1.5% (nitric acid - HNO3). Example: 0.75 liters of HNO3 in 50 liters of water. Temperature: 65 to 75ºC.

- Rinse for 5 minutes to remove residues.

- Circulate caustic soda in a closed system for 20 minutes, preferably at a temperature close to 80°C.

- Rinse to remove the caustic soda.

- Circulate nitric acid at a temperature of 65 to 75°C for 20 minutes.

- Rinse until all chemical residues are completely removed from the system.

- Rinse with sanitizer for 5 minutes at a maximum temperature of 24°C.

Contact